Manufacturing Accounting: Streamline Your Business with Experts

Building a comprehensive understanding of the value of your WIP inventory is key to ensuring that you have a good understanding of your business’s profitability. Establish clear guidelines for what constitutes direct versus indirect costs, and regularly review these classifications to ensure accuracy. Maintaining consistent and accurate cost allocation helps ensure your financial data reflects the true cost structure of your production processes.

Calculate Cost of Goods Sold (COGS):

Proper allocation not only aids in setting competitive pricing but also ensures profitability and clarifies which products are most cost-effective. Direct costs manufacturing accounting are expenses that can be directly traced to specific products, such as raw materials and direct labor. These costs are essential for determining the cost of goods sold (COGS) and developing effective pricing strategies. With numerous accounting methods and costing strategies that manufacturing businesses can use, it is always important to ensure that cash flow is maintained to avoid hiccups during production. Manufacturing business owners can also consider financing options such as invoice factoring to maintain a streamlined flow of money in their operations regardless of the market outlook.

Budgeting and Forecasting for Manufacturers

Calculate and allocate manufacturing overhead costs, such as rent, utilities, depreciation on manufacturing equipment, and indirect labor, to production activities. Use allocation bases like machine hours, direct labor hours, or square footage to distribute overhead costs to products or jobs. It integrates various functions, including production planning, inventory management, and financial reporting, providing a comprehensive view of the business. This method considers numerous future costs that might impact the final cost of producing the product.

- This is an exciting time for the manufacturing industry, but it’s also a time of uncertainty.

- Effective cash flow forecasting is essential for manufacturing operations, allowing companies to anticipate funding needs for raw material purchases, production scheduling, and capital equipment investments.

- Since physical inventory counts are time-consuming, few companies do them more than once a quarter or year.

- This is vital for producing accurate financial statements and making informed decisions.

- One of the most powerful applications of manufacturing accounting is analyzing profitability at the product and customer level.

How can manufacturing software improve accounting processes?

- Inventory valuation methods play a significant role in manufacturing accounting as they determine how inventory is valued on financial statements.

- In this article, I will break down manufacturing accounts, explain key concepts, and provide practical examples to help you grasp this critical aspect of business accounting.

- It is prepared to calculate the cost of goods produced during the year and it is also known as the production account.

- This involves identifying potential concerns in the production process and finding appropriate solutions for them.

- Accounting for manufacturing businesses involves recording, analyzing, and managing financial transactions related to the production of goods.

He’s visited over 50 countries, lived aboard a circus ship, and once completed a Sudoku in under 3 minutes (allegedly). Technology and global trends are always changing – and so must a manufacturing business if it wishes to stay agile. By the time you finish upgrading your systems, the world may have evolved to make them obsolete. Once a product has been manufactured, its costs will typically be transferred from the manufacturing account to the income statement along with the price markup. Ideally, data should move freely between production lines and the back office, meaning you have accurate real-time data. This software can be used to extract data and analyze trends, improve efficiency, and make the best business decisions.

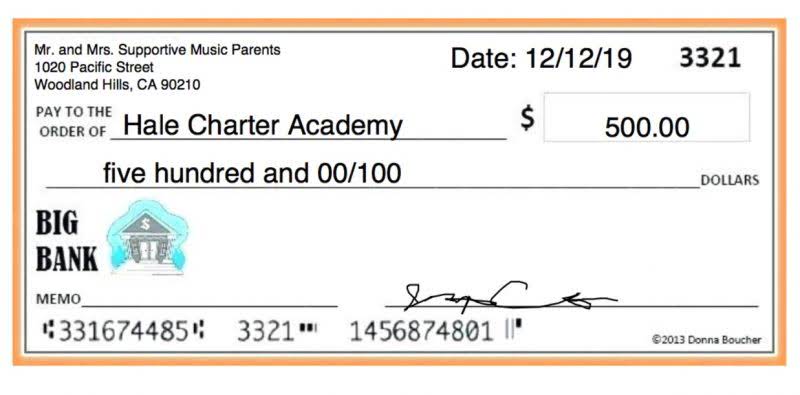

- Get $30 off a tax consultation with a licensed CPA or EA, and we’ll be sure to provide you with a robust, bespoke answer to whatever tax problems you may have.

- Manufacturing accounting is a group of inventory and production management processes used for monitoring and controlling the costs involved with manufacturing products.

- Standard costing is useful if you are making similar products or large quantities of a specific product.

- Accurate tracking of labor costs is essential, as many manufacturers struggle to properly allocate these expenses to specific products or production runs.

- Standard costing is widely used in manufacturing accounting in the Philippines due to its simplicity and efficiency.

- As we have seen, manufacturing accounting includes insight into processes absolutely fundamental for ensuring the financial health of your manufacturing business.

Budgeting processes in factories and other industries rely considerably on historical data and production expenses to help How to Invoice as a Freelancer managers make an informed estimate for future budgets. There are likely hundreds of software tools available that help with accounting for manufacturing costs. You’ll need to speak with your accountant or financial advisor and consider your current budget before making an informed decision.

The Role of Accounting Software

Additionally, manufacturing accountants must be able to accurately analyze data related to production cost trends to make informed decisions about future investments or strategies. The direct costing method in manufacturing accounting allows businesses to only consider variable costs without becoming encumbered with fixed expenses. Direct costing is primarily useful in undertaking pricing decisions for the short term.

Key manufacturing accounting software features

The resulting distortion leads to substandard pricing strategies and misguided business decisions about which products to emphasize or eliminate. Reviewing your accounting processes with a high attention to detail can make the difference between opportunity and loss. That’s why we’ve listed the six most common manufacturing accounting oversights here—plus the best practices you can employ to avoid them. Now that we have gained a deeper understanding of the theoretical foundations of the manufacturing accounting process flow, let’s explore how it functions in real-world scenarios.

The Role of Technology in WIP Accounting

But regardless of the method, manufacturers must ensure WIP is updated regularly and reflects real-time production activity. Failure to do so can distort profitability and lead to misinformed pricing and investment decisions. Job costing is common for manufacturers that produce custom or small-batch items, where costs are assigned to specific projects. Process costing, by contrast, is better suited for continuous production environments, where costs are spread across all units manufactured in a given period. Some businesses use standard costing, which applies pre-set cost assumptions to simplify calculations, while others adopt activity-based costing (ABC) to allocate expenses more precisely. While service companies focus primarily on labor costs and https://pecuarioesteripharma.com/2022/02/08/enrolled-agent-salary-pay-guide-for-enrolled-2/ time, manufacturers must navigate the intricate world of inventory valuation, material costs, and production efficiency––plus labor costs and time.

ქართული

ქართული Русский

Русский